Lakeland Engineering Equipment Company and Acrotech, Inc. Automate “Most Sophisticated Roll Bending Machine”

OVERVIEW

Acrotech, Inc. came to Lakeland Engineering Equipment Company in search of specific electrical components and automation expertise for a custom roll bending machine Acrotech was building for a new OEM customer. The machine needed to be automated to meet the customer’s specific requirements and goals, including a higher-level of machine operator safety and material rolling in one continuous pass. Having bought from Lakeland before and knowing the type of service, expertise, and resources that the Lakeland team had, Acrotech called on Lakeland to find the best solution that would fit their customer’s needs. Together with Lakeland’s team of resources, they were able to provide Acrotech with a fully-automated solution inclusive of the requirements outlined by their customer.

Acrotech, Inc. came to Lakeland Engineering Equipment Company in search of specific electrical components and automation expertise for a custom roll bending machine Acrotech was building for a new OEM customer. The machine needed to be automated to meet the customer’s specific requirements and goals, including a higher-level of machine operator safety and material rolling in one continuous pass. Having bought from Lakeland before and knowing the type of service, expertise, and resources that the Lakeland team had, Acrotech called on Lakeland to find the best solution that would fit their customer’s needs. Together with Lakeland’s team of resources, they were able to provide Acrotech with a fully-automated solution inclusive of the requirements outlined by their customer.

Read the full case study below or download the PDF.

THE PROJECT

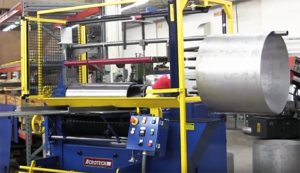

A large OEM of drums for washing and drying machine manufacturers approached Acrotech with the need for a roll bending machine that was fully-automated and included muting functions, machine position monitoring, and more. This was a new territory for Acrotech. Being a longtime customer of Lakeland Engineering Equipment Company, Acrotech reached out to Lakeland to automate and program a solution with the required electrical components.

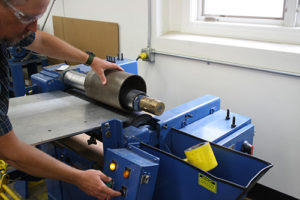

Acrotech, Inc. manufactures custom roll bending machines – their unique, patented K•Prene® Urethane is on the roller and is the heart of the system. Each roll bending machine is customized according to the customer’s requirements and specific goals. “Every machine is different,” said Andy Oliver, Owner and President of Acrotech Inc. “75% of each machine is standard, and from there up and out, it could be a whole different ball game.”

Acrotech, Inc. manufactures custom roll bending machines – their unique, patented K•Prene® Urethane is on the roller and is the heart of the system. Each roll bending machine is customized according to the customer’s requirements and specific goals. “Every machine is different,” said Andy Oliver, Owner and President of Acrotech Inc. “75% of each machine is standard, and from there up and out, it could be a whole different ball game.”

“Instead of building a manual run machine, the machine this OEM wanted had to be fully-automated,” said Andy. “We had never built a machine with these advanced capabilities and extended safety features before this project.”

THE CHALLENGE

The goals that Acrotech’s customer wanted to achieve with this machine centered on the safety of their machine operators and the quality of the rolled material that could be produced from the use of this machine.

The main objectives of the custom-built roll bending machine included:

The main objectives of the custom-built roll bending machine included:

- Improve quality, save time, and enhance safety

- Roll steel or aluminum on the machine for their drums in one continuous pass

- Implement an overall higher level of machine operator safety

- Take the manual labor out of the operation by automating the roll bending machine

- Enable muting functions so the machine would automatically but temporarily stop the safety device to let materials travel through the machine without stopping the motion

- Monitor the position of the arm on the roll bending machine

- Control and detect the timing and distance of materials

THE SOLUTION

Lakeland worked with Joe White, Plant Manager – Engineering, at Acrotech along with the team of engineers and programmers at one of Lakeland’s partner resources, Control Assemblies, to develop, integrate, and program a complete safety system. “Lakeland has a big umbrella of who they can reach out to – that’s one of the greatest benefits,” said Joe.

Lakeland worked with Joe White, Plant Manager – Engineering, at Acrotech along with the team of engineers and programmers at one of Lakeland’s partner resources, Control Assemblies, to develop, integrate, and program a complete safety system. “Lakeland has a big umbrella of who they can reach out to – that’s one of the greatest benefits,” said Joe.

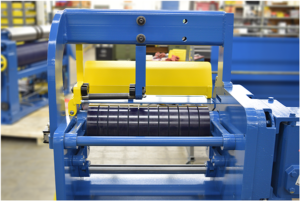

Diane Lynch within the Purchasing department at Acrotech was also a crucial point of contact for Lakeland. The solution developed for the custom roll bending machine included a PLC, safety light curtain and mirrors, proximity sensors, limit switches, safety interlocks, and more.

A Banner safety PLC was integrated to automate the electromechanical process of the rolling machine so the foot switch was only used at the start of the process. Pepperl + Fuchs proximity sensors, ABB safety interlocks, and Honeywell limit switches were also included into the overall design. These electrical controls were a necessary integration to ensure the machine arm was up and locked in place before the roll bending action could be performed. Banner safety light curtains and mirrors were integrated to perform the required muting functions and to protect machine operators from injury.

“The muting functions on the machine allowed part to travel through the light curtain at the right time to rest on part support outside the machine,” explained Joe. “The machine goes back into service when the rolling action begins.”

“The muting functions on the machine allowed part to travel through the light curtain at the right time to rest on part support outside the machine,” explained Joe. “The machine goes back into service when the rolling action begins.”

The custom built roll bending machine was complete with the electrical components and programming needed to meet all of the customer’s needs and safety requirements. “You helped us build one of the most sophisticated roll bending machines we’ve ever built,” said Andy. “We don’t get into automation every day, but when we do, we go to Lakeland.”

Today, Acrotech has been in the roll bending business for 20-years with 2018 being their best year yet. “Typically if a customer buys one machine, they come back,” said Andy. “We have customers who have bought several machines. The quality and longevity of the machines are what sets us apart.”

“The process of working with Lakeland has been great – they’re always quick to respond,” said Joe. “I know enough to be dangerous. Sometimes we think we know what we need but Lakeland helps ensure it is the right selection, finds alternatives to obsolete products, and is readily available for start-ups when we need it. [Todd] is my go-to.”

“The process of working with Lakeland has been great – they’re always quick to respond,” said Joe. “I know enough to be dangerous. Sometimes we think we know what we need but Lakeland helps ensure it is the right selection, finds alternatives to obsolete products, and is readily available for start-ups when we need it. [Todd] is my go-to.”

Watch the roll bending machine in action below.

For questions about this case study or to learn more about Lakeland Engineering Equipment Company, contact us at sales@lakelandengineering.com. Read on to learn more about Acrotech, Inc.

THE HISTORY + FUTURE OF ACROTECH

Acrotech began in 1984 when three owners including Dale Oliver bought out urethane division from Di Acro / Houdaille Industries. In 2004, Dale Oliver handed the business to his two sons, Andy and Paul Oliver. Working in the company since he was 15-years-old, Andy Oliver worked his way up to now sole owner and president of the company. As their customer’s needs expanded, so did Acrotech’s capabilities, product offerings, and facility.

Acrotech began in 1984 when three owners including Dale Oliver bought out urethane division from Di Acro / Houdaille Industries. In 2004, Dale Oliver handed the business to his two sons, Andy and Paul Oliver. Working in the company since he was 15-years-old, Andy Oliver worked his way up to now sole owner and president of the company. As their customer’s needs expanded, so did Acrotech’s capabilities, product offerings, and facility.

Today, Acrotech, Inc. has over 9,000 customers and specializes in custom urethane molding and custom-built roll bending machines. “There are a lot of opportunities we haven’t tapped into yet with the roll bending machines,” said Joe. “We just touched the surface on the controls and that’s exciting. We’re currently working on a machine to roll parts with multiple radiuses.”

While Acrotech continues to expand their roll bending business, their largest vertical is the custom poured urethane. They can produce parts cost effectively, compared to machining or injection molding. Going from five urethane color options to nearly 20 today, Acrotech continues to push the envelope with forward thinking in a niche market. “People send us prints or sample parts to be made in urethane – since urethane is a much better product in certain applications and lasts longer,” said Andy. “More often than not, we take on the challenge, and that’s how we’ve grown so much over the years.”

“We have stock molds onsite for our many repeat customers – we even have a room dedicated to that,” Andy said as he showed the impeccably clean warehouse and explained the areas of their business. “Acrotech pours all durometers (thickness’) of urethane – as soft as bubble gum or as hard as a bowling ball.”

“We have stock molds onsite for our many repeat customers – we even have a room dedicated to that,” Andy said as he showed the impeccably clean warehouse and explained the areas of their business. “Acrotech pours all durometers (thickness’) of urethane – as soft as bubble gum or as hard as a bowling ball.”

When asked what sets them apart, Andy humbly commented, “What I would consider unique is our attention to detail. We won’t just send you anything – we’re proud of the quality we deliver. We do almost everything in-house – we have our own machine shop, engineering team, design team, and together we take projects from the beginning to the end.”

Joe enjoys the smaller company aspect at Acrotech. “We’re a true job shop and react real quickly. As an engineer, I’m always intrigued by the variety of services we can provide for all types of applications and functions.”

Joe enjoys the smaller company aspect at Acrotech. “We’re a true job shop and react real quickly. As an engineer, I’m always intrigued by the variety of services we can provide for all types of applications and functions.”

The future of Acrotech, Inc. is sure to be bright with their continuous drive to innovate and expand their offerings to best meet the needs of their customers. To learn more about Acrotech, Inc., visit their website.

For questions regarding this case study or to learn more about Lakeland Engineering Equipment Company, contact us at sales@lakelandengineering.com.