- Product Spotlight

How Pepperl+Fuchs Makes IIoT Easy with IO-Link Sensors and Masters

- By Emily Hagel

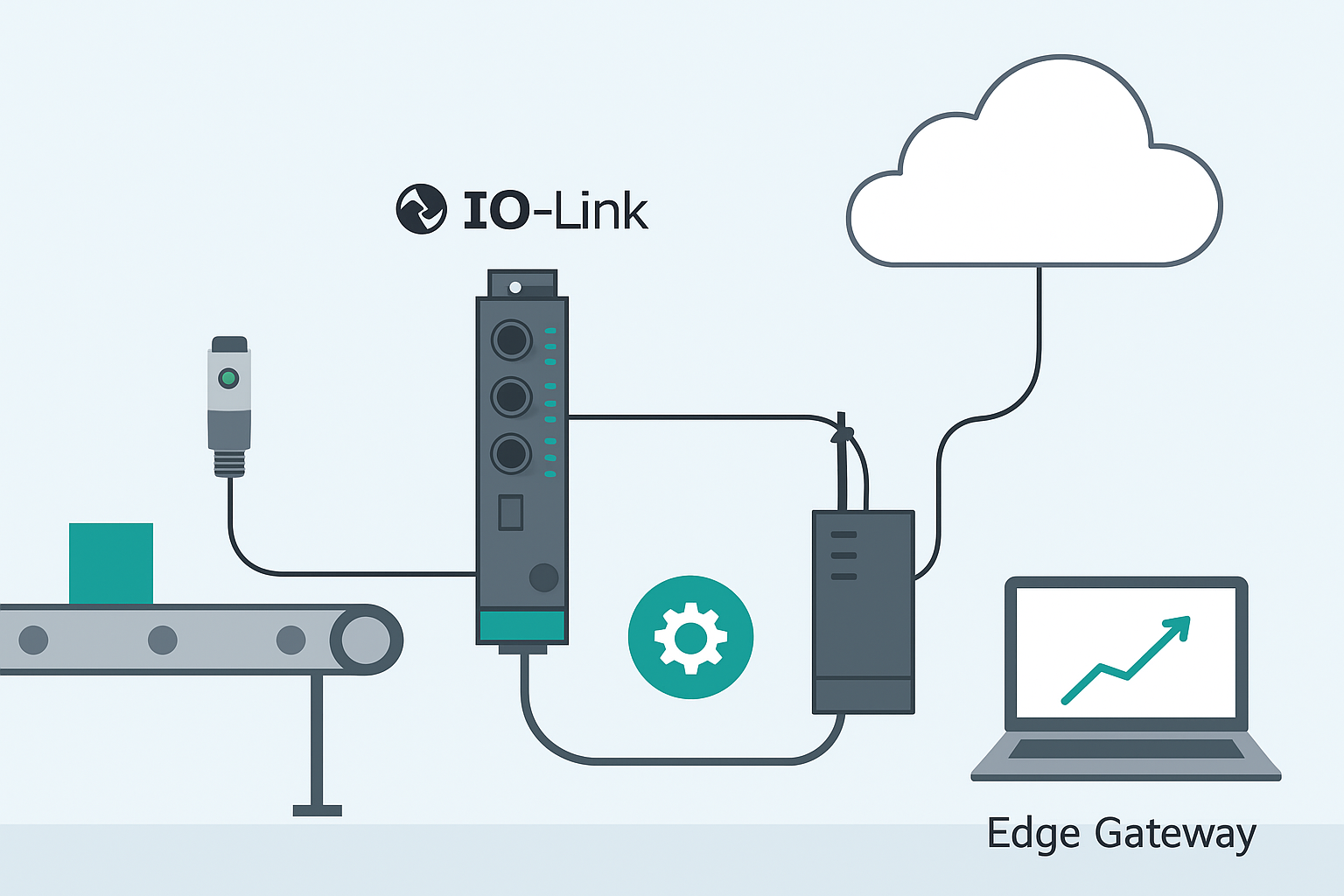

The Industrial Internet of Things (IIoT) can sound complicated, cloud connections, edge computing, predictive maintenance, and more. But with the right hardware, even small steps can unlock big wins in uptime and efficiency. That’s where Pepperl+Fuchs IO-Link sensors and masters come in. They provide a simple, cost-effective way to bring smart data out of your machines and into your control system or cloud.

What Is IO-Link?

IO-Link is an open communication standard that allows sensors and actuators to exchange far more than just an “on/off” signal. Instead of sending one basic value, IO-Link devices share detailed information like:

Measured values (flow, distance, vibration, etc.)

Device diagnostics (temperature, error codes, run time)

Configuration data (parameters that can be set remotely)

This means your plant gets not just raw data, but actionable insights that improve troubleshooting and maintenance.

Pepperl+Fuchs IO-Link Sensors

Pepperl+Fuchs offers a wide range of IO-Link enabled devices, including:

Proximity sensors for detecting parts or materials

Photoelectric sensors for fast, precise object detection

Ultrasonic sensors for distance and fill-level measurement

Vibration and rotary encoders for condition monitoring

Each of these devices does more than sense — they also share their health status and configuration, which helps your maintenance team act faster when issues occur.

The Role of IO-Link Masters

Sensors need a gateway to deliver data into your control system or the cloud. That’s the job of Pepperl+Fuchs IO-Link Masters (such as the ICE2 and ICE3 series).

These devices act as translators, connecting up to eight IO-Link devices and passing their data into:

Your PLC (via PROFINET, EtherNet/IP, or Modbus TCP)

Edge or cloud systems (via OPC UA or MQTT)

With MultiLink™ technology, Pepperl+Fuchs IO-Link Masters can send data to both control systems and IIoT platforms simultaneously — so operations and maintenance teams get the information they need without disrupting production.

Why This Makes IIoT Simple

Many plants hesitate to adopt IIoT because they worry about complexity or cost. Pepperl+Fuchs helps simplify the journey by offering:

Plug-and-play compatibility: IO-Link is vendor-neutral and works across multiple platforms.

Retrofit options: You don’t need to replace legacy machines — just add IO-Link masters and upgrade a few sensors to start collecting smart data.

Scalable solutions: Start with one machine or line, then expand plant-wide.

Predictive maintenance made practical: Smart diagnostics reduce unplanned downtime without needing a full-scale digital transformation.

Getting Started with IO-Link at Your Plant

If you’re curious about IIoT but unsure where to begin, start with one line or machine that causes frequent downtime. Replace a few key sensors with Pepperl+Fuchs IO-Link versions, connect them through a master, and use the built-in diagnostics. Within weeks, you’ll see the benefits of faster troubleshooting and better data visibility.

The Industrial Internet of Things doesn’t have to be overwhelming. With Pepperl+Fuchs IO-Link sensors and masters, plants can take small, affordable steps toward smarter operations. By unlocking diagnostic data and connecting it to your control and cloud systems, you’ll improve uptime, increase safety, and prepare your plant for the future of automation.