Parallel Connection and Redundancy of Power Supplies – What is the difference?

Are you in need of a higher total power for your system or machine, or want to ensure a reliable power supply? Common solutions include the parallel connection or establishing a redundant power supply system.

More total power – How does a parallel connection work?

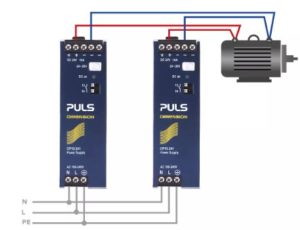

By using power supplies in parallel, the load current required by the system or machine is supplied jointly by several power supply units.

What types of parallel connection are there for power supplies?

You can classify power supplies, connected in parallel, into two groups: power supplies with and without load sharing.

Power supplies without load sharing, it is not possible to ensure a balanced current distribution. This can lead to overload and overheating of a power supply, which can develop into a failure of the device.

Power supply units with load sharing ensure a balanced current distribution. This prevents one or more devices from being overloaded. A distinction can be made here between active and passive load sharing.

How do I set up a parallel connection correctly?

To achieve a balanced load between the power supply units connected in parallel, the output voltages must be set as precisely as possible to the same value. Each power supply manufacturer designs its output circuit differently. Therefore, it is recommended to use identical power supply units of the same brand. This enables reliable adjustments and prevents unforeseen problems during operation.

To minimize the risk of overheating devices, power supplies must be arranged next to each other and not mounted on top of each other. Take into account the specifications on the minimum spacing between the devices according to the installation manuals.

Higher availability – What is a redundant power supply system?

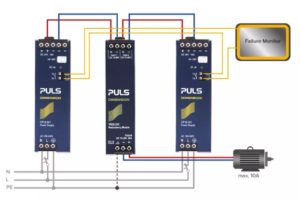

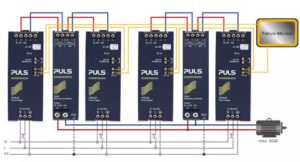

In a redundant power supply system, more power supplies are used than are actually required to supply the load. The units share the total load among themselves (= paralleling). If one of them fails, the total load is carried by the remaining power supply units. Should the defective power supply unit have a short circuit in the process, a protects it from being fed back into the short circuit.

This reliable power supply thus ensures the high availability of the machine or system. Redundant power supply systems are used especially when a power supply failure is intolerable.

One application is in the automotive industry, where the cost of a production shutdown far exceeds the cost of setting up a redundant power supply system from the beginning. Another example is the food industry: Due to hygiene regulations, systems that have come to a standstill must be completely cleaned before they can be put back into operation. This maintenance is time-consuming and cost-intensive and can be prevented by a redundancy system.

There are several redundant systems to choose from. Read about them here.

1+1 Redundancy

N+1 Redundancy