- Product Spotlight

RTD Temperature Transmitters vs Thermocouples: Choosing the Right Pyromation Solution for Your Application

- By Emily Hagel

When it comes to temperature measurement in industrial environments, accuracy, reliability, and efficiency are critical. At Lakeland Engineering Equipment Company, we partner with trusted manufacturers like Pyromation to deliver top-tier temperature sensing solutions tailored to your application needs. Two of the most common temperature sensors—RTD (Resistance Temperature Detector) transmitters and thermocouples—serve similar purposes but differ significantly in performance, cost, and durability.

In this blog, we break down the key differences between Pyromation’s RTD temperature transmitters and thermocouples to help you choose the right fit for your operation.

What Are RTDs?

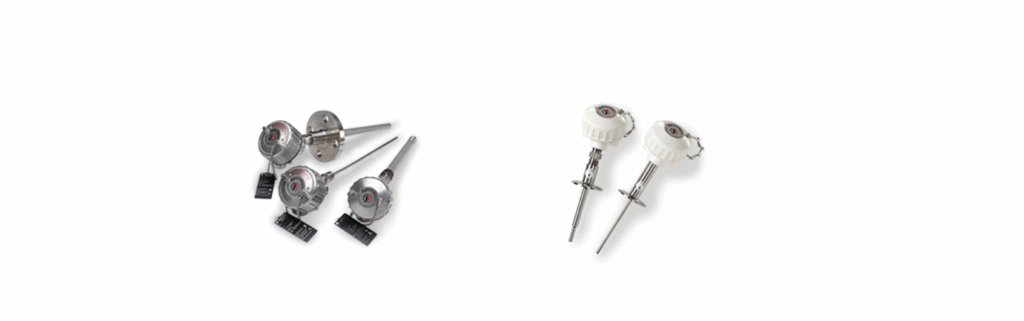

RTD Temperature Transmitters measure temperature by correlating the resistance of the RTD element (typically platinum) to temperature. Pyromation offers precision-engineered RTD assemblies with transmitters that convert resistance signals into standardized output signals (4-20 mA or digital), making integration seamless and accurate.

RTD transmitters are ideal when:

Precision and stability are top priorities—like in food & beverage, pharmaceuticals, and HVAC.

You need standardized signal output for easy integration into a control system.

You’re operating within moderate temperature ranges.

Long-term reliability reduces maintenance and downtime.

Pyromation’s RTD transmitters, including explosion-proof and DIN rail-mounted options, deliver industry-leading performance with easy installation and field calibration.

What Are Thermocouples?

Thermocouples generate a voltage based on the temperature difference between two dissimilar metals. Pyromation manufactures thermocouples in various types (J, K, T, etc.) to suit diverse applications and temperature ranges.

Thermocouples are ideal for:

High-temperature applications, such as metal processing, combustion systems, or kilns.

Environments with mechanical vibration or harsh conditions.

Applications requiring a quick response to temperature changes.

Budget-sensitive operations where lower sensor cost is essential.

Pyromation offers a broad line of thermocouples with rugged sheath materials, multiple calibration types, and fast lead times to meet your needs.

Lakeland’s Expert Insight

Lakeland Engineering is more than a distributor—we’re your engineering and automation partner. Our team helps you evaluate:

Application temperature range

Environmental conditions

Desired accuracy

Integration with existing control systems

Long-term maintenance and lifecycle cost

We work closely with Pyromation to ensure our customers receive the best-fit sensor solutions that enhance operational efficiency, product quality, and sustainability.