U1000 Matrix Drive Mitigates Harmonics + Saves Space

Yaskawa U1000 Matrix Drive

The Yaskawa U1000 Matrix Drive is a Clean Power VFD and solution for regenerative power applications. The drive provides low harmonics, with less than 5% iTHD at the input terminals of the VFD and is ideal for a host of industrial applications including the water/wastewater industry. In water and wastewater facilities, the majority of energy is being filtered through the variable frequency drives (VFD). This creates distortion and facilities need a solution to mitigate this. Instead of the bulky, traditional multi-pulse drives, Yaskawa U1000 Matrix drive provides a space-saving solution that simplifies cabinet wiring, provides more effective harmonic mitigation, and does not require the purchase of an expensive transformer like the multi-pulse drives.

The design of the drive obviates the DC bus by using nine bi-directional IGBTs (insulated-gate bipolar transistors) in a matrix arrangement to generate the variable frequency AC output directly from the AC input. With no DC bus to charge, the associated non-linear input current draw can be eliminated.

For drives that use a matrix design like the U1000, any input phase can be connected directly to any output phase at any time. The key to a drive’s matrix operation is its ability to turn the bi-directional switches on and off at the correct times to generate the proper output voltage and frequency required to operate the motor.

Matrix Design and Regenerative Voltage

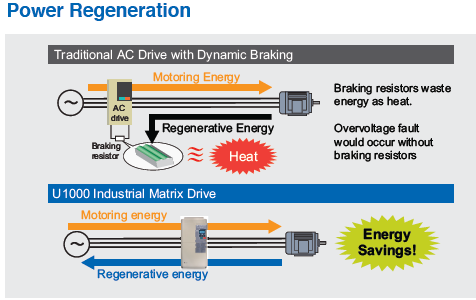

In addition to the ultra-low harmonics and near-unity power factor, the U1000’s design also provides energy savings through regeneration. When a motor is being driven by a load, as opposed to driving the load, it acts as a generator, sending voltage back to the VFD.

In conventional drives, dynamic braking resistors can be used to divert the regenerative energy away from the VFD and prevent a DC bus over-voltage condition. The Yaskawa U1000 design enables the regenerative power to be re-distributed to other loads on the system, which reduces the power required for entire system. This may lead to an overall reduction in the utility bill for the machines in this system.

Matrix Design and EcoMode

The main benefit of VFDs is to enable a fixed-speed motor to operate at variable speeds. However, some applications require full speed for significant periods of time. In these cases, the U1000 can close the appropriate IGBTs to provide a direct connection between input and output to the motor, thus maximizing efficiency without requiring conventional VFDs to use contactors to bypass the drive. This mode also prolongs the life of the VFD by allowing all the IGBTs to “rest” while maintaining at a steady on/off position.

VFD Power Monitoring

In addition to the U1000’s unique matrix design, the VFD can monitor power in several ways to give instant feedback on energy savings. When provided with the dollar amount per kWh billing rate, the display on the VFD can show the following information on request:

- Power output

- Power consumption

- Regenerative power

- Power saved

- Power bill

Comparing VFDs with a Matrix or Conventional Design

There are also other means to mitigate the harmonics of conventional VFDs. These include active front-ends and multi-pulse transformers, which require significant additional components in combination with the VFD, all of which mean added bulk, cost, and wiring connections. The Yaskawa U1000 matrix drive accomplishes low harmonics all within the drive – three wires in, three wires out, making it the fastest and easiest VFD to commission for regenerative and low harmonic applications.

The U1000 is available in a wide range of voltage and horsepower ratings, typically up to 100 HP at 240 V and 800 HP at 480 V. Look for the same Underwriters Laboratories (UL), Canadian Standards Association (CSA), CE, and Restriction of Hazardous Substances Directive (RoHS) certifications and support for induction, surface permanent magnet, and interior permanent magnet motors. With heightened requirements for sustainability and compliance to IEEE 519-2014, matrix VFDs like the Yaskawa U1000, provide a cost-efficient, space-efficient, and energy-efficient means for applications. The Yaskawa U1000 Matrix Drive also won the Control Engineering’s 2016 Engineers’ Choice Award.

Lakeland Certified Drives Specialists

Lakeland Engineering Equipment Co. has carried the Yaskawa line for over a decade. We have certified drives specialists on-staff to provide application assistance, start-up services and troubleshooting. Contact us today to request local support or a quote.

Learn More About the U1000 Matrix Drive: